Safety First: Reducing Risks Around Machinery in the Warehouse.

Warehouses are the heartbeat of Australia’s supply chain — fast-paced, dynamic, and full of moving parts. But with that comes serious responsibility. Every year, too many workers are injured or worse due to unsafe practices around heavy machinery.

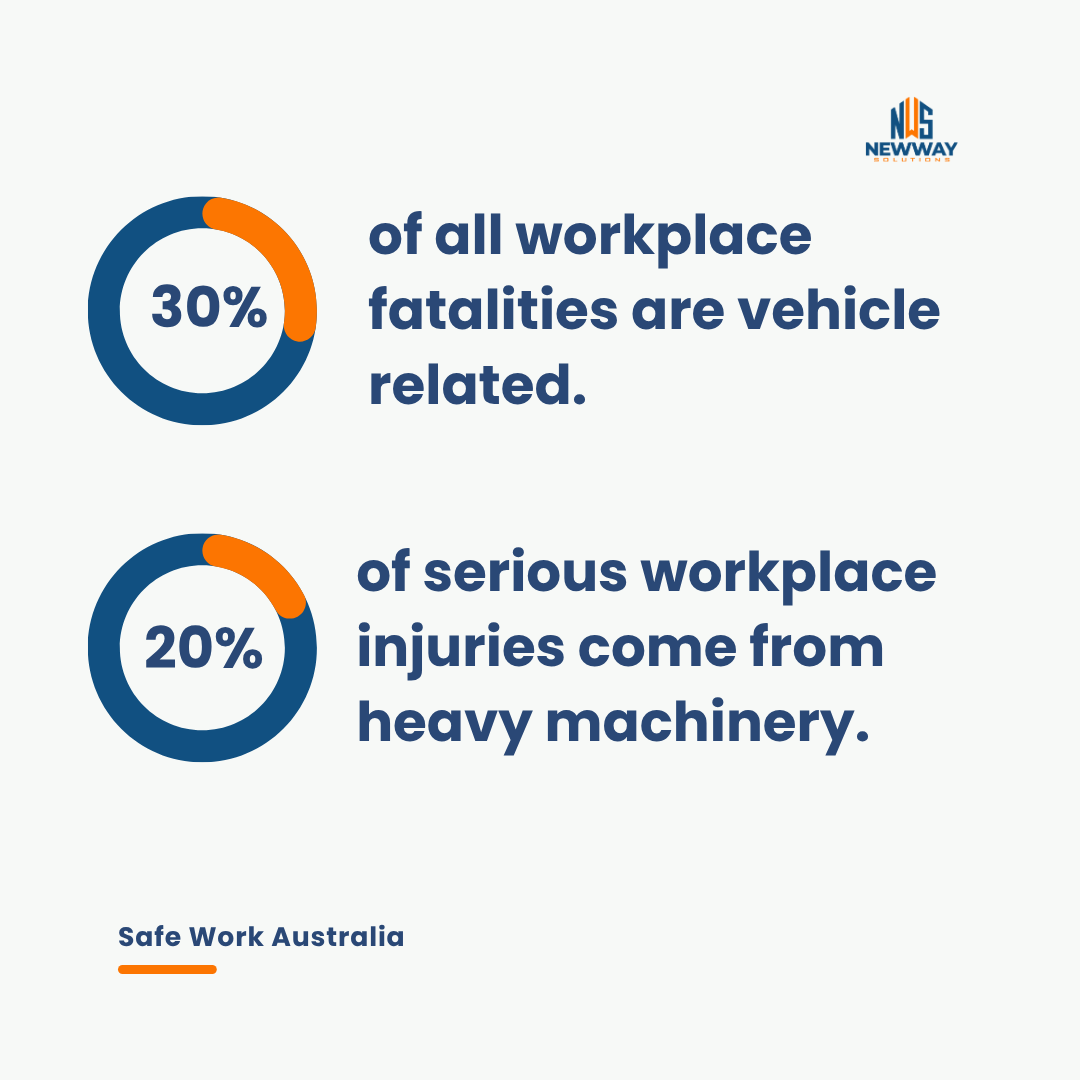

In fact, 30% of all workplace fatalities are vehicle-related, and 20% of serious injuries involve heavy machinery incidents. These numbers remind us that safety isn’t just a policy — it’s a culture.

Why Machinery Safety Matters

From forklifts and pallet movers to conveyors and automated systems, machinery helps warehouses operate efficiently. But when safety procedures are overlooked, these same machines can become hazards.

Common causes of warehouse incidents include:

Poor visibility and blind spots during forklift operations

Lack of operator training or refresher courses

Inadequate separation between pedestrians and vehicles

Fatigue or rushing to meet deadlines

Poor maintenance or faulty equipment

Safe Operation of Vehicles and Heavy Machinery

Operating vehicles and heavy machinery requires caution and strict adherence to safety protocols. Follow these essential safety practices.

Comprehensive Training

Ensure you are properly trained and authorised to operate any vehicle or machinery. Each workplace has different requirements-familiarize yourself with specific controls and safety features.Use Of Personal Protective Equipment (PPE)

Always wear the appropriate PPE, including hard hats, gloves, and safety boots, when operating machinery.Follow Safety Procedures

Adhere to operational guidelines, including speed limits, load capacities, and navigation protocols. If unsure, stop and consult your supervisor before proceeding.

By following these practices, we can ensure a safer working environment for everyone.

Regular Maintenance and Inspections

Regular maintenance and inspections are required to keeping vehicles and equipment safe and functional. Workplace equipment maintenance is managed by the client, but it’s important you understand your role in inspecting and reporting.

Scheduled Maintenance: The client will manage the maintenance of equipment. Pending the use and demand to equipment it could be they follow the manufacturer’s guidelines for routine maintenance of machinery and vehicles. This may include oil changes, brake check and tire inspections.

Daily Inspections: Part of your role could be to conduct pre-operation checks, including fluid levels, breaks, lights and safety features. Report any issues or damage immediately to your supervisor.

Documentation: A record will be kept by the client of all maintenance and inspections performed.

We encourage you to take proactive approach to vehicle and equipment safety:

Review Safety Protocols: Ensure you understand your workplace safety guidelines regarding vechile and machinery operation.

Conduct Inspections: If you are a machine or equipment operator, you maybe responsible for pre-check checks. Stay vigilant in your routine checks and report any concers to your supervisor immediately.

Report Issues: If you notice any defects or potential safety hazards, please report them to your supervisor or the safety team immediately.

By focusing on vehicle and equipment safety, we can significantly reduce the risk of accidents and injuries in the workplace. Thank you for your commitment to maintaining a safe and productive environment.

Stay safe and take care!

- The Safety Team!